8 aspects of Quality that will improve Productivity

Increase Quality to increase Productivity

If you see people in your business as the accelerator for productivity then when you want to "step on the gas" you are just stepping on people.

Innovation comes from people who take joy in their work.

Lets look at how understanding and making improvements to quality will give you the productivity increases you are looking for.

Good News.

"Good news!" the mild mannered manager says as he saunters over to your desk coffee cup in hand.

"The executive team have only called for productivity increases this quarter.. no cuts!"

"By what method?" you dare to ask already knowing the answer.

"By working smarter and harder of course!"

Want to increase your own productivity or productivity in your business?

By what method? Hint: it is a quality answer. This is not a quick fix. Our ingredients for success

- Happy, engaged people,

- Well documented and effective process

- Measurements of success

- A bent on increasing quality.

We will get to quality. Lets start with the idea of productivity.

Productivity is a measurement - not an actionable task. You can put focus on the number but as with any quota based management approach it will lead to employee demoralization and poor results in the long term.

"Measurements of productivity are like accident statistics.

They tell you there is a problem, but they don't do anything about the accidents."

William E. Conway

The 3 basic steps to moving anything forward are:

- Knowing where you are at the moment.

- Defining where you want it to be.

- Building the bridge and taking the step to get you there.

These are simple but powerful questions. It is ok to stop and think about this. It is what you call planning.

Yes two of these steps involve measurements. Measurements are important! If you don't know where you are before you start you won't know if you've gone anywhere. If you don't know where you want to be than any road gets you there - because you haven't cared where you are going. But measurements do not lead staff or inspire personal action. It is hard to set appropriate goals. It is even harder to provide guidance on how to achieve them. You should hire smart people and get out of their way. But you also need to tell them not only what you want done, but why and by what methods are appropriate.

Often like in our situation above - we receive a destination and not a map or support on how to get there. Not really much of a plan anywhere in sight there is there? Leadership?

So lets think about a better way. A method for management that gets us closer to the right track. One of our favorites is the "System of Profound Knowledge". Forget the overly deep name and lets have a quick look.

W Edwards Deming put forward a method for management built around the 4 pillars of:

Appreciation for a system:

Seeing your business as a system and understanding how it works.

Knowledge of variation:

Understanding types of variation and how to determine if a process is under

control. Changing things that you do not understand is tampering no matter how

well intentioned.

Theory of knowledge:

Commitment to understand what is happening through iterative experimentation

and challenge. No blind assertions.

Psychology:

Understanding people

For working on productivity through quality lets start with understanding people.

The thing about people.. We want to do great work!

You cannot increase productivity by telling people to increase their productivity.

"So everyone is just going to have to start rolling up our sleeves" he offers sipping his coffee quietly.

"We are the problem? You mean we have been slacking?"

"No - Just dig a bit deeper and get more."

"You are saying that everything else around us, the system, does not require improvement and all we need to do is more of what we are already doing?

"Umm.. but there will be a bonus!"

We want to take pride in the work we do. We love mastery - the idea of being good at the things people respect us for.

Research shows that once people are at a fair pay base, monetary rewards do not motivate the way managers hope they do. When jobs involve even the slightest amount of thinking, extrinsic rewards systems reduce performance. People are best inspired by intrinsic motivation.

For the modern workforce the three core intrinsic motivators are Autonomy, Mastery and Purpose. Dan Pink has researched, spoken and written about this quite extensively.

In brief:

Autonomy.

We want the freedom to work how we like, and have influence over our own rules and conditions. We have the need to direct our own lives and our own work. This is why micromanaging employees is a bad idea. Can people choose their tasks, or at least the order they are done? or the time it is done? or the tools and methods involved?

Mastery.

We want to improve our skills, we want to continuously learn and get better at what we do. When you no longer feel like you are growing it is the beginning of the end for your current job. This is why training and R&D time is a must. Are they assigned enough "goldilocks tasks" that are the just right level of challenging?

Purpose.

We want to contribute to something bigger than ourselves. We want to feel our life/ work is meaningful and it serves a higher purpose, aligned with our values. This is why clear strategy and goals mean so much. Do you and your people know what their work is used for? How it fits into the overall plan for the business?

If effort is actually the reason there is constrained productivity then resolving this issue is not something an employee can do. It is the job of management to connect the appropriate people into the appropriate environment.

Any increase or alignment in autonomy, mastery or purpose is required to inspire the intrinsic motivations to produce results.

"So I actually wanted to talk to you first as you are the expert when it comes to this process" He says. You smile and nod as you continue to listen.

"We think we have a solid opportunity to break into a new market with this product. Can you imagine what that would mean for their customers if they used our product that way?"

You think about how awesome that would be and he continues."You know we would have problems supporting that kind of demand on our volumes. Can you spend at least a day a week this quarter working through how we can experiment to try overcome those limitations? If not maybe there is a new feature we could add that would help?"

Armed with pursuit of mastery, some autonomy and fueled by purpose you set to thinking about volume and value..

The thing about productivity.. the problems aren't always where the results are

There are 2 kinds of productivity you can increase:

Physical productivity (the focus on Efficiency)

This is the quantity of output produced by one unit of production input in a unit of time. For example, a certain process can produce 10 units of output per hour. If you can increase this to 12 units of output per hour you have increased productivity. It is natural to think about this in terms of a factory or production line. It does however apply to any paradigm such as jobs per hour. Phone calls made. Project tasks completed. When we want to improve physical productivity we are asking:

Do you want to do more tasks in the same amount of time?

Do you want to make more things in the same amount of time?

Economic productivity (the focus on Effectiveness)

This is the value of the output obtained from one unit of input. For example, if a worker produces in an hour an output of 2 units, whose price is $10 each, then his productivity is $20. If you change this to produce 1 unit of output worth $30 you have increased productivity. This may be about how you prioritize your time. The particular types of things you do or produce. When looking to increase economic productivity we are asking:

Do you want to increase the value of a task produced in the same amount of time?

Do you want to achieve a different higher value task in the same amount of time?

Notice time plays into all of these questions? What volume and/or quality can we get done in the hours of the day we have.

How Productivity can be improved

To understand how to improve something you need to first understand what limits it. This shows you the knobs that can be turned to influence the outcome.

Physical productivity is constrained by:

- The volume of input or source material we have.

- The quality of that input.

- The technology that is used in the process.

Economic productivity is constrained by everything physical productivity is and:

- Creativity. Can your skilled labor create something or a solution that is special.

- Pricing. Things are always worth what someone is willing to pay for it.

- Demand. No point increasing the production of something that isn't wanted.

Increase physical or economic productivity by examining the same 3 places.

- The production process itself - the technology tools of the trade.

- How we go bout doing the work, or making the thing.

- Can we change technology?

- Can we use alternative methods?

- Do we need more of some kind of input to be able to improve this?

- The decision making and governance process surrounding it - how we manage

the process, the red tape and rules.

- Are there steps that can be mitigated?

- Are there reductions in time frames in the decision making processes to be made?

- Is everyone who needs to be involved in the loop?

- The external parties and environments in which you operate - what we get and

who we have to deal with to get it.

- Is the quality on inputs appropriate?

- Are we sourcing inputs from the most appropriate place?

So how do we scale source inputs, our ability to handle them, improve technology, utilize creativity, reduce pricing and increase demand?

The thing about quality.. nobody is unhappy when it goes up.

"Improve Quality, you automatically improve productivity." - DR. W EDWARDS DEMING

Focus on improving quality - not productivity (you will get productivity for free.)

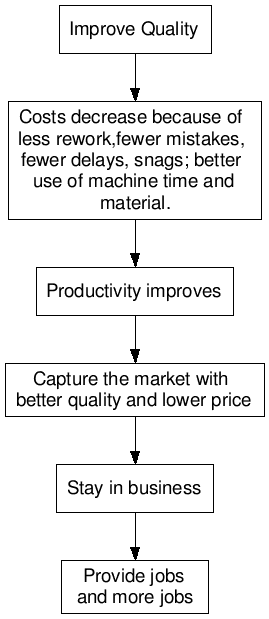

The Deming Chain Reaction

20 years ago in his book "Out of the Crisis" Deming wrote about the chain reaction that focusing on quality triggers. It looks like this:

Cost savings come from the idea that: "If you don't have time to do it right you must have time to do it again. "

This may also look very manufacturing orientated and you would be right in thinking so. However these principals transfer and apply to all kind of product and service based businesses.

What do we mean by quality? Quality of the product or service? Quality of the processes that build them? Quality of the technology used in their creation? Yes.

So what do we mean by quality in this context? Deming and Juran write about quality as being the Fitness for purpose or Fitness for use which is orientated towards the customer.

All of us have a customer and a supplier. We get our inputs from somewhere and pass our outputs onto someone else to consume. They are not always external parties. Your customer might be another department who is the next step in a delivery process. We all operate in a larger ecosystem. To understand the fit for use understand your customers use of what you produce.

Aim your quality initiatives at the needs of a consumer. To plan an increase in quality you then need to focus on an aspect for improvement. David Garvin defined these 8 dimensions of quality:

Performance

Objective, measurable attributes. How fast does it go?

Features

The bells and whistles outside of the core. What can this one do that others

can't?

Reliability

The likelihood that a failure will occur within a time period. Will it be

available when needed?

Conformance

The extent that something meets established standards and/or rates of errors

and mistakes in service. Does it do what we expect it to?

Durability

The length of life. How long can something be used for until it no longer

make economic sense to do so.

Serviceability

The way things are fixed when they break or go wrong. This covers most aspects

of communication and interaction with customers.

Aesthetics

Subjective assessment of how something looks, feels sounds or tastes. Being

subjective you cannot please everyone.

Perceived Quality

The subjective reputation based on the above qualities.

You cannot pursue quality improvements in all of these areas concurrently. Some of these aspects are reinforcing whereas others are at the expense of one another. Understanding your customer and the tradeoffs they are willing to make helps you build a strategic competitive advantage.

Beware suboptimization

A Systems performance is a product of the interactions of their parts. Every system is a part of an even greater system. Improving or optimizing one link in a chain may not create the best outcome for the system as a whole. Rusell L. Ackoff of systems thinking fame often cited the example:

If you study cars from around the world… Take the best engine, the best brakes, etc from different models – you can’t put them together into a working car (or anything close to the best car) The parts wouldn't fit.

Taking what we know.. Some examples

You can't eat the elephant all at once. So you eat it one bite at a time. But which bite? Is this even the elephant to be eaten.

We work towards our people being intrinsically motivated by the pursuit of Mastery while working with Purpose and in Autonomy. We want to increase productivity so we identify the type and possible constraints. Constraints in mind we look to define the fit for purpose based on customer need. Knowing the need we identify and look at what dimensions of quality would best serve that need.

Lets work through an example. We want to increase the Sales Team productivity in the form of % of converted leads. We could look at the methods and processes that the sales team work with their marketing qualified leads. However by viewing our customer acquisition process as a system we can see that the Sales Team conversion process has both inputs and outputs. In this case the inputs are the leads marketing provide. Acknowledging that a constraint of quality on inputs can affect outputs we can optimize in the Marketing Team processes to help the Sales Team first.

| Key | Value |

|---|---|

| Initiative | Improve lead quality |

| Customer | Sales Team |

| Supplier | Marketing Team |

| Aspect of Quality | Conformance |

| Productivity Type | Economic |

| Pursuit of Mastery | Crafting and executing campaigns that precision target audiences. |

| Purpose | Alert and connect to customers who actually have the problems our solutions solve. |

Another around personal productivity.

When intrinsically engaged in the work you are doing and in pursuit of productivity, you are really chasing quality.

You want to finish every day feeling like you have achieved more than you do at the moment. First you examine your own system you work within and your situation to understand:

- Do I have the freedom to make the choices I want to make this better?

- Do I know what skill I am working towards increasing my mastery in?

- Do I know why I am working towards the outcomes I am?

| Key | Value |

|---|---|

| Initiative | Increase instances of reaching Inbox zero. |

| Customer | Everyone that communicates with you |

| Supplier | Everyone that communicated with you |

| Aspect of Quality | Serviceability |

| Productivity Type | Physical |

| Pursuit of Mastery | Time management |

| Purpose | Serve the people around you in a timely fashion and increase their perception of your helpfullness/mastery. |

Great news

"Great news!" manager man says as he saunters over to your desk coffee cup in hand.

"The executive team have only called for quality increases this quarter"

"By what method?" you dare to ask excited to know the answer.

"We are dedicating time to improving that process thats been bugging us"

Conclusion

- Innovation comes from people who take joy in their work.

- People are not your productivity problem.

- If people are your problem it is a management problem.

- Quota based management is bad. Lead with quality objectives

- There are 2 types of Productivity and it is constrained by a knowable set of factors.

- Improving aspects of quality touches and loosens all of those constraints.

- Quality Improves Productivity.

Stop caring about productivity and dedicate yourself to improving your quality.

Focusing on quality gives you time to be more productive.